Streamline Yard Ops, Slash Dwell Time & Eliminate Check-In Chaos

PowerYMS gives you real-time visibility into trailers, moves, and dwell, without spreadsheets, radio chaos, or a long implementation cycle.

Your Yard and Gate, Optimized

Enhance driver productivity, optimize operations, and improve safety with the PowerYMS cloud-based yard and gate management system. With a modular design, you only pay for what you need and expand as you grow. PowerYMS provides:

.png?width=512&height=512&name=stopwatch%20(3).png)

50% Faster Yard Checks

Real-time tracking ends trailer hunts and wasted hours, increasing operational efficiency and reducing frustration for your team.

.png?width=512&height=512&name=dollar-symbol%20(1).png)

Lower Costs at Any Scale

Accurate, defensible timestamps slash detention fees and disputes—savings range from thousands per yard to millions across networks.

.png?width=512&height=512&name=flash%20(1).png)

Rapid Deployment

Go live in weeks with devices you already own—no RFID tags or Wi-Fi upgrades required. Get value faster with minimal setup.

Bring Clarity and Control to Yard Operations

PowerYMS is a modular yard management platform designed to eliminate blind spots across yard and gate operations, without adding complexity or forcing a rip-and-replace of existing systems. PowerYMS goes live in weeks using devices you already own, with no RFID tags, Wi-Fi upgrades, or long implementation cycles. PowerYMS provides:

-

50% Faster Yard Checks (PowerYard)

Real-time trailer visibility eliminates yard hunts and wasted hours, helping teams focus on what needs to move next instead of what’s missing. -

Lower Gate-Related Costs and Fewer Disputes (PowerGate)

Accurate, defensible time-stamped gate events reduce detention fees and disputes — delivering savings from thousands per yard to millions across multi-site networks. -

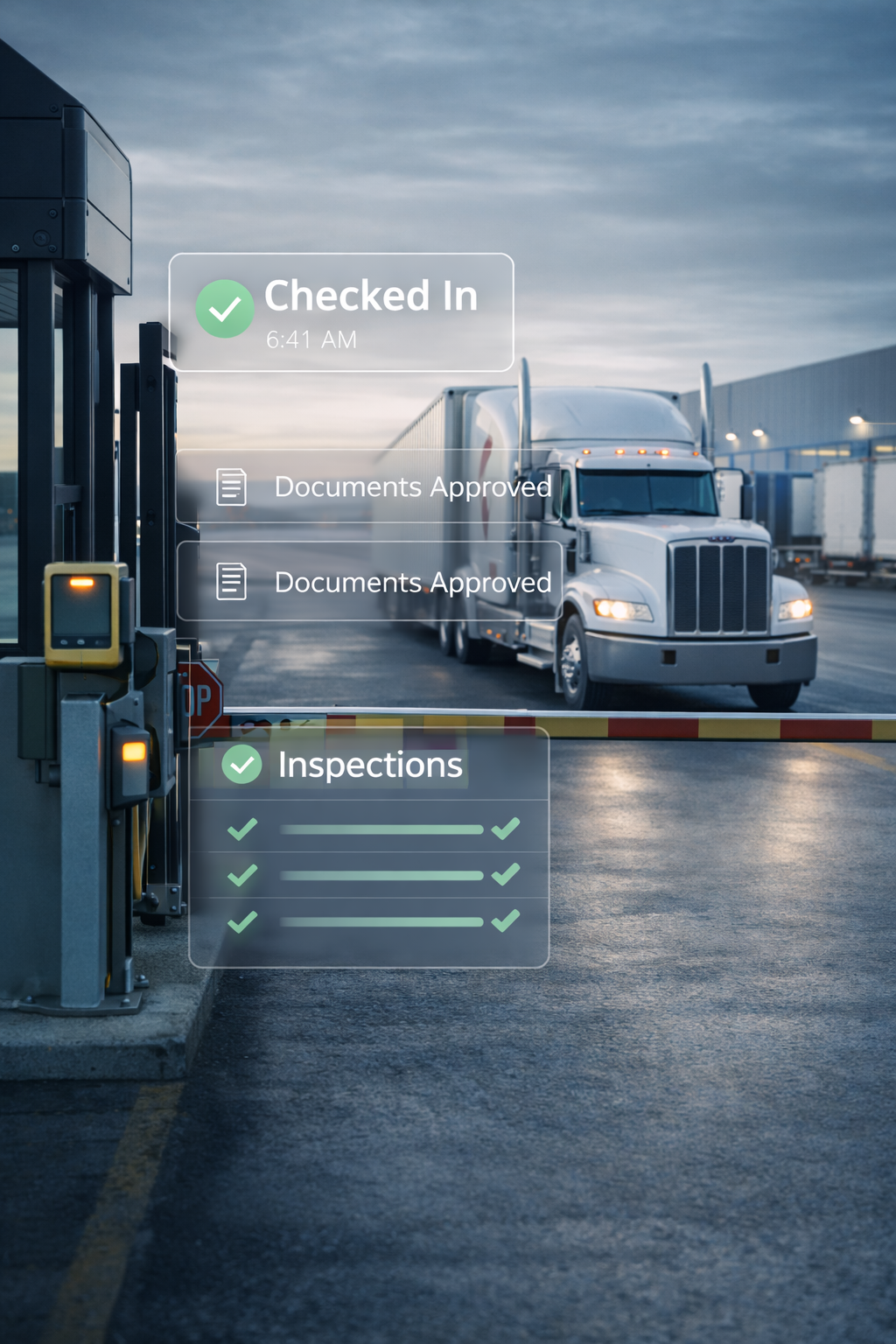

Smoother Arrivals With Fewer Yard Surprises (EZCheck-In)

Driver pre-check ensures paperwork, appointment details, and requirements are handled before arrival — reducing rework, bottlenecks, and unexpected delays at the gate.

Optimize Your Yard, Gate, and Driver Tasks

.png?width=512&height=512&name=Frame%201%20(14).png)

Yard Visibility & Management

Real-time inventory, task automation and cold-chain monitoring keep every asset in view

.png?width=512&height=512&name=Frame%201%20(15).png)

Gate Automation

Digitized check-in/out, mobile gate attendants and inspection tools eliminate queues and manual errors

.png?width=512&height=512&name=Frame%201%20(16).png)

Driver Pre-Check

Let drivers complete paperwork and self-check-in on any device; cut detention costs and disputes

Yard Visibility & Management

Real-time inventory, task automation and cold-chain monitoring keep every asset in view

Gate Automation

Digitized check-in/out, mobile gate attendants and inspection tools eliminate queues and manual errors

Driver Pre-Check

Let drivers complete paperwork and self-check-in on any device; cut detention costs and disputes

PowerYMS: Yard & Dock Visibility

Problem

Manual yard checks and scattered paperwork create blind spots that slow down operations. Trailers go missing, loaders waste hours hunting, and managers struggle to keep dwell times and compliance under control—driving up costs and delaying schedules.

Solution

PowerYMS replaces manual checks with real-time data and clear digital tasking in yards and docks. Every trailer and driver task is tracked in one system, so staff always know where assets are and what should be done next.

Real-time Tracking

Queue-based Task Management

Reefer Monitoring

Exportable History

Who it's for: Warehouse and distribution-centre operators, 3PLs, manufacturers, chemical facilities and port/intermodal terminals needing accurate asset visibility.

"A major distribution centre cut detention fees by over 50%, improved trailer scheduling and saved three hours per day by unifying tracking and dwell data."

PowerYard: Yard & Dock Visibility

Problem

Manual yard checks and scattered paperwork create blind spots that slow down operations. Trailers go missing, loaders waste hours hunting, and managers struggle to keep dwell times and compliance under control—driving up costs and delaying schedules.

Solution

PowerYMS replaces manual checks with real-time data and clear digital tasking in yards and docks. Every trailer and driver task is tracked in one system, so staff always know where assets are and what should be done next.

PowerYMS Features

- Real-time inventory control and digital yard checks

- Queue-based task management with clear, radio-free instructions

- Optimized trailer pool management (FIFO)

- Reefer temperature monitoring and cold-chain alerts

- Yard/dock spot allocation with exportable history

PowerYard provides real-time yard and dock visibility to:

PowerYard provides real-time yard and dock visibility to:

Real PowerYMS Results: A major distribution centre cut detention fees by over 50%, improved trailer scheduling and saved three hours per day by unifying tracking and dwell data.

PowerGate: Gate Automation

Problem

Manual gate operations create bottlenecks, incomplete inspections, and costly detention. Without accurate timestamps, operators spend too much time piecing together conflicting data from carriers—leaving them exposed to disputes and expensive detention fees.

Solution

PowerGate digitizes every gate transaction so processing is fast, inspections are accurate, and all driver documentation is timestamped and stored automatically.

Mobile Gate Attendant

Mobile Gate Attendant

Customizable Inspection Forms

Customizable Inspection Forms

On-site Asset List

On-site Asset List

Automatic Timestamps

Automatic Timestamps

Document Management

Document Management

Gate History Export

Gate History Export

Who it's for: Gate attendants, security teams, and high-throughput yards at distribution centers or ports that need to reduce queues, cut disputes, and eliminate manual data collection.

"We reduced gate check-in times by 33% at our distribution yard. PowerGate is saving us more than 20 hours per week!"

PowerGate: Gate Automation

EZCheck-In: Driver Pre-Check

Problem

When drivers arrive without the right documents or data, everything slows down. Queues build at the gate, staff scramble to validate paperwork, and disputes arise later when records don't line up. The result is wasted hours, higher labor costs, and costly billing disputes.

Solution

With EZCheck-In, drivers pre-submit BOLs and other documents on any device and can self-check in via phone or tablet before getting to the gate, or at a kiosk upon arrival. Dispatchers gain real-time visibility of inbound loads, while operations teams capture accurate, defensible timestamps to prevent disputes.

Direct Integration

Multi-Device Support

Real-Time Visibility

Automated Validation

Document Imaging

Who It's For: Carriers, 3PLs, e-commerce fulfillment hubs, and distribution centers that need to cut wait times, reduce labor costs, and eliminate disputes at the gate.

"Using PowerYard's EZCheck-In, a national parcel carrier reduced invoice disputes by 72%, thus recovering $2M in detention overpayments."

Key Benefits

Cut Wait Times

Reduce Labor Costs

Reduce Labor Costs

Eliminate Disputes

Eliminate Disputes

Real-Time Visibility

Real-Time Visibility

| Feature |

PowerYMS

|

PowerGate

|

EZCheck-In

|

|---|---|---|---|

|

Real-time inventory control

|

|

|

|

|

Task management & queue-based tasks

|

|

|

|

|

Digital yard task execution

|

|

|

|

|

Trailer pool management (FIFO)

|

|

|

|

|

Reefer temperature checks

|

|

|

|

|

Yard/dock spot allocation

|

|

|

|

|

Task & yard history export

|

|

|

|

|

Digitized gate transactions

|

|

|

|

|

Mobile gate attendant

|

|

|

|

|

Custom inspection forms |

|

|

|

|

Asset list & WMS click-to-copy

|

|

|

|

|

Tractor/trailer timestamps

|

|

|

|

|

Document management

|

|

|

|

|

Driver pre-checks

|

|

|

|

|

Self-check-in (BYOD)

|

|

|

|

|

Inbound visibility & driver chat

|

|

|

|

|

Record validation & surveys

|

|

|

|

|

Ruggedized tablets

|

|

|

|

|

BYOD

|

|

|

|

Problem

Manual gate operations create bottlenecks, incomplete inspections, and costly detention. Without accurate timestamps, operators spend too much time piecing together conflicting data from carriers—leaving them exposed to disputes and expensive detention fees.

Solution

PowerGate digitizes every gate transaction so processing is fast, inspections are accurate, and all driver documentation is timestamped and stored automatically.

PowerGate Features

- Digitized gate transactions and mobile gate attendant

- Simplified check-in/out with customizable inspection forms

- On-site asset list and click-to-copy data entry into WMS

- Automatic tractor and trailer timestamps

- Document management and gate history export

PowerGate reduces queues, cut disputes, and eliminate manual data collection for:

Real PowerYMS Results: “We reduced gate check-in times by 33% at our distribution yard. PowerGate is saving us more than 20 hours per week!” – Yard Operations Lead

PowerGate: Gate Automation

Problem

Manual gate operations create bottlenecks, incomplete inspections, and costly detention. Without accurate timestamps, operators spend too much time piecing together conflicting data from carriers—leaving them exposed to disputes and expensive detention fees.

Solution

PowerGate digitizes every gate transaction so processing is fast, inspections are accurate, and all driver documentation is timestamped and stored automatically.

Mobile Gate Attendant

Mobile Gate Attendant

Customizable Inspection Forms

Customizable Inspection Forms

On-site Asset List

On-site Asset List

Automatic Timestamps

Automatic Timestamps

Document Management

Document Management

Gate History Export

Gate History Export

Who it's for: Gate attendants, security teams, and high-throughput yards at distribution centers or ports that need to reduce queues, cut disputes, and eliminate manual data collection.

"We reduced gate check-in times by 33% at our distribution yard. PowerGate is saving us more than 20 hours per week!"

EZCheck-In: Driver Pre-Check

Problem

When drivers arrive without the right documents or data, everything slows down. Queues build at the gate, staff scramble to validate paperwork, and disputes arise later when records don't line up. The result is wasted hours, higher labor costs, and costly billing disputes.

Solution

With EZCheck-In, drivers pre-submit BOLs and other documents on any device and can self-check in via phone or tablet before getting to the gate, or at a kiosk upon arrival. Dispatchers gain real-time visibility of inbound loads, while operations teams capture accurate, defensible timestamps to prevent disputes.

PowerYMS Features

- Real-time inventory control and digital yard checks

- Queue-based task management with clear, radio-free instructions

- Optimized trailer pool management (FIFO)

- Reefer temperature monitoring and cold-chain alerts

- Yard/dock spot allocation with exportable history

PowerYMS Solution Module Features

Choosing the right yard solution shouldn’t be complicated. This grid shows what’s included in each PowerYMS module so you can quickly see which one solves your most pressing challenges today—and how adding more unlocks even greater value.

PowerYard

Advanced Yard Management

220/months

220/months- Real-time inventory control

- Task management & queue-based tasks

- Digital yard task execution

- Trailer pool management (FIFO)

- Reefer temperature checks

- Yard/dock spot allocation

- Task & yard history export

- Ruggedized tablets

PowerGate

Streamlined Gate Operations

- Digitized gate transactions

- Mobile gate attendant

- Custom inspection forms

- Asset list & WMS click-to-copy

- Tractor/trailer timestamps

- Document management

- BYOD

PowerYard

Advanced Yard Management

- Real-time inventory control

- Task management & queue-based tasks

- Digital yard task execution

- Trailer pool management (FIFO)

- Reefer temperature checks

- Yard/dock spot allocation

- Ruggedized tablets

PowerGate

Streamlined Gate Operations

- Digitized gate transactions

- Mobile gate attendant

- Custom inspection forms

- Asset list & WMS click-to-copy

- Tractor/trailer timestamps

- Document management

- BYOD

EZCheck-In

Driver Self-Service Portal

- Driver pre-checks

- Self-check-in (BYOD)

- Inbound visibility & driver chat

- Record validation & surveys

- Ruggedized tablets

Case Studies

Every yard is different—but the results are consistent. Customers across industries use PowerYMSto cut detention fees, eliminate disputes, and keep freight moving.

Explore results below, filterable by PowerYard (Yard & Dock Visibility), PowerGate (Gate Automation), or EZCheck-In (Driver Pre-Check).

Unilever

90% Fewer Detention Invoices | $2M+ Annual Savings

Modules: PowerGate, EZCheck-In

- 90% fewer detention invoices

- $2M+ annual savings

90% Fewer Detention Invoices | $2M+ Annual Savings

Modules: PowerGate, EZCheck-In

Challenge

Unilever relied on manual gate logs and carrier-provided timestamps that couldn’t be verified. When detention invoices arrived, the operations team lacked defensible data to challenge them, leading to prolonged disputes and frequent write-offs.

Solution

PowerGate digitized every gate transaction while EZCheck-In captured arrival and departure data directly from drivers. Manual logs were replaced with system-generated timestamps trusted by operations, finance, and carriers.

Results

-

$2M+ annual reduction in detention spend

-

90% drop in detention invoices

-

Disputes resolved quickly—or stopped entirely

-

Ops and finance teams freed from constant back-and-forth

.jpg?width=512&height=394&name=trucks%20outside%20a%20large%20distribution%20center%20(1).jpg)

Healthcare Distribution Center

Detention Fees Reduced from $40K+ to $83/Month

Modules: PowerGate, EZCheck-In

- Detention cut to $83 a month

- Disputes eliminated

Detention Fees Reduced from $40K+ to $83/Month

Modules: PowerGate, EZCheck-In

Challenge

Solution

Results

-

Monthly detention reduced from $40,000+ to $83

-

Carrier disputes effectively eliminated

-

Assessorials managed proactively

-

Carrier disputes effectively eliminated

- Co-located Operations Specialist

.jpg?width=512&height=394&name=semi%20trucks%20with%20engines%20in%20the%20front%20arriving%20outside%20an%20ECommerce%20Fulfillment%20Hub%20(1).jpg)

HVAC Manufacturer

Trailer Hunt Time Cut in Half

Modules: PowerYMS

Challenge: Loaders wasted hours searching for trailers

Solution: Real-time yard visibility and trailer tracking

- 50% faster trailer hunts

- 1–2 hours saved per shift

Trailer Hunt Time Cut in Half

Modules: PowerYMS

Challenge

Limited yard visibility led to misplaced trailers, delayed loads, and disrupted dock schedules.

Solution

PowerYMS provided real-time trailer inventory and FIFO-based yard organization.

Results

-

50% reduction in trailer hunt time

-

1–2 hours saved per shift

-

Improved dock scheduling accuracy

-

Higher loader productivity and morale

.jpg?width=512&height=394&name=14263%20(1).jpg)

National Parcel Carrier

Accurate Detention Billing | $2M Recovered

Modules: EZCheck-In

- 72% fewer disputes

- $2M recovered

Accurate Detention Billing | $2M Recovered

Modules: EZCheck-In

Challenge

Detention invoices were routinely disputed due to weak or inconsistent timestamps, forcing finance teams to write off legitimate charges.

Solution

EZCheck-In introduced automated, geo-stamped arrival and departure records tied to each tractor and trailer.

Results

-

72% reduction in detention disputes

-

$2M recovered in lost revenue

-

Faster billing cycles

-

Greater confidence in invoice accuracy

.jpg?width=512&height=394&name=10810%20(1).jpg)

Major Distribution Center

Centralized Visibility | 50%+ Less Detention

Modules: PowerYMS, PowerGate

- 50%+ reduction in detention

- 3 hours/day saved

Centralized Visibility | 50%+ Less Detention

Modules: PowerYMS, PowerGate

Challenge

Six separate systems were used to track trailers, dwell, and gate activity, forcing managers to piece together information manually.

Solution

PowerYMS centralized yard visibility while PowerGate digitized gate transactions into a single platform.

Results

-

50%+ reduction in detention

-

3 hours saved per day

-

Improved trailer turns and dock utilization

-

Fewer operational surprises during peak periods

.jpg?width=512&height=394&name=2152008994%20(1).jpg)

Food Processor

Faster Check-Ins | $52K Annual Impact

Modules: EZCheck-In

- 30% faster check-ins

- $52K annual impact

Faster Check-Ins | $52K Annual Impact

Modules: EZCheck-In

Challenge

Paper-based check-ins and document errors regularly disrupted dock flow and required follow-up work.

Solution

EZCheck-In allowed drivers to submit documents and images before arrival, giving dock teams validated information upfront.

Results

-

30% faster check-ins

-

$16K labor savings

-

$36K dock efficiency gains

-

Smoother, more predictable dock operations

“Before PowerYard, check-ins were slow and paperwork mistakes constantly caused delays at the dock. Now drivers can pre-submit everything, and our team works from accurate records. Check-ins are faster, errors are gone, and the whole dock flows more smoothly.” – Operations Manager, Food Processing Facility

.jpg?width=512&height=394&name=2152031818%20(1).jpg)

HVAC Manufacturer – Trailer Hunt Time Cut in Half

Challenge

Solution

Results

-

Dock scheduling accuracy improved by 25%

-

Loaders gained back 1–2 hours per shift

-

Trailer hunt times reduced by 50%

.jpg?width=512&height=394&name=2148943341%20(1).jpg)

Major Distribution Center – Digitized Gate Operations

Challenge

Solution

Results

-

Over $30K in annual savings

-

20+ hours saved weekly

-

Gate check-ins reduced by 33%

.jpg?width=512&height=394&name=1921%20(1).jpg)

Cold Chain Distribution Facility – Simplified Compliance

Challenge

Solution

Results

-

Reduced risk of costly regulatory penalties

-

Cut 14 hours/week from compliance tasks

-

100% audit readiness with trusted digital records

.jpg?width=512&height=394&name=132623%20(1).jpg)

E-Commerce Fulfillment Hub – Visibility Without a Gate

Challenge

Solution

Results

-

Removed off-hour blind spots that previously caused weekly delays

-

Eliminated manual yard walks; WMS updates now instant and automated

-

Full 24/7 visibility into arrivals and departures

.jpg?width=512&height=394&name=136203%20(1).jpg)

Logistics Provider – Real-Time Task Execution

Challenge

Solution

PowerYMS introduced Digital Yard Task Execution, replacing manual logs with automated digital tracking. Managers gained 24/7 visibility into tasks, enabling them to spot and resolve issues proactively.

Results

-

15% increase in yard throughput

-

Managers resolving issues in real time instead of after the fact

-

Eliminated manual logging, saving drivers 2 hours per shift

.jpg?width=512&height=394&name=4593%20(1).jpg)

Large Distribution Yard – Eliminated Gate Guesswork

Challenge

Solution

Results

-

Reduced driver waiting time by 30%

-

2 hours/day saved on WMS updates

-

Full visibility into off-hour gate activity

.jpg?width=512&height=394&name=63731%20(1).jpg)

Consumer Goods Warehouse – Smarter Dock Assignments

Challenge

Solution

Results

-

Improved overall scheduling accuracy and throughput

-

Increased dock worker productivity by 15%

-

Fewer dock delays and 40% less rework

Frequently Asked Questions

How can PowerYard optimize my yard operations and drive profitability?

PowerYard streamlines yard management processes, shortens task durations, and enhances driver productivity, resulting in more efficient operations and increased profitability.

What return on investment (ROI) can I expect from using PowerYard?

By streamlining operations, reducing errors, and optimizing resource allocation, PowerYard provides a cost-effective solution that yields rapid ROI. Take advantage of our no-risk trial to experience the benefits firsthand.

What sets PowerYard apart from other yard management solutions?

PowerYard stands out with its comprehensive visibility, efficient task management, and hassle-free deployment. Our user-friendly interface and highly-configurable system offer flexibility to meet your specific needs, while keeping the focus on essential features that enhance productivity and reduce costs.

Is PowerYard compatible with our existing systems and technologies?

Yes, PowerYard is a versatile platform that can be easily integrated with your existing systems, such as transportation management systems (TMS) or warehouse management systems (WMS), enabling seamless data flow and enhanced operational efficiency.

How does PowerYard improve communication within the yard?

PowerYard enhances communication by empowering drivers with a comprehensive task queue and direct communication through the in-tool chat functionality. This reduces the need for radio chatter, minimizes interruptions, and fosters clear and efficient communication among yard personnel.

How does PowerYard improve task accuracy and accountability?

PowerYard ensures accurate and reliable yard inventory management, providing precise tracking of inventory and clear documentation of task completion. Accurate time stamps and task durations foster transparency and accountability, eliminating discrepancies and fostering improved relationships.

Can PowerYard handle high volumes of yard assets?

While,PowerYard is designed to handle yard assets of various volumes, making it suitable for businesses with both high and low asset volumes, its affordability and balanced technology (robust, but not overly complex) makes it particularly well-suited for yards with 1-4 tractors.

How can PowerYard reduce driver frustration?

PowerYard automates task assignment and provides clear, queue-based instructions, minimizing downtime and confusion.

Can PowerYard handle compliance requirements like CT-PAT?

Yes, PowerYard ’s customizable inspection forms ensure compliance for every transaction.

What makes PowerYard unique?

Our platform combines user-friendly design, full visibility, and rapid deployment (go-live in just four weeks) with no upfront infrastructure costs.

Even more PowerYard TMS results...

-

Major Distribution Center: Centralized Visibility & Reduced Detention

Challenge: Manual processes and scattered documents made it difficult to track trailers, manage dwell times, and schedule efficiently—causing delays and detention fees.

Solution: PowerYard unified tracking, dwell data, and gate activity in one real-time platform—reducing six systems to three.

Results:

* 50%+ reduction in detention fees

* Improved trailer scheduling via real-time dwell insights

* Saved three hours/day by eliminating manual data handling

-

Cold Chain Distribution Facility: Simplified compliance and custom data collection

Challenge: CT-PAT and audit requirements demanded manual data capture and custom forms.

Solution: Configurable Pre-Check Portal with digital recordkeeping.

Results:

* Trusted digital records for compliance

* 2 hours saved daily

* $36K in annual productivity savings

-

National Parcel Carrier: Validating detention with digital accuracy

Challenge: Inconsistent timestamps led to billing disputes and lost detention revenue.

Solution: Automated geo-stamped check-in/out data.

Results:

* 72% fewer invoice disputes

* More accurate billing

* $2M saved in detention overpayments

-

HVAC Manufacturerr: Trailer Hunt Time Cut in Half

Challenge: Loaders spent excessive time searching for trailers, disrupting dock flow. Lack of real-time tracking created inefficiencies in trailer allocation.

Solution: Real-Time Inventory Control and Optimized Trailer Pool Management

Results:

* Trailer hunt times reduced by 50%

* Significant gain in loader productivity

* Improved dock scheduling accuracy

-

E-Commerce Fulfillment Hub: Visibility without a gate

Challenge: No gates or structured check-ins left drivers guessing, causing inventory errors and delays.

Solution: Driver Pre-Check with real-time arrival/departure visibility.

Results:

* Off-hour events captured systematically

* Faster yard checks and WMS updates

* $36K in annual time savings

-

Major Distribution Center: Digitized gate operations

Challenge: Gate operations bogged down with manual processes, leading to significant delays during peak hours. Drivers often waiting 15+ minutes to check in.

Solution: PowerYard YMS enabled digitized gate transactions with real-time BOL submissions eliminated paperwork, manual entries, and errors.

Results:

* Gate check-ins reduced by 33%

* 20+ hours saved weekly

* Over $30K in annual savings

-

Cold Chain Distribution Facility: Simplified compliance and custom data collection

Challenge: CT-PAT and audit requirements demanded manual data capture and custom forms.

Solution: Configurable Pre-Check Portal with digital recordkeeping.

Results:

* Trusted digital records for compliance

* 2 hours saved daily

* $36K in annual productivity savings -

Logistics Provider: Real-time task execution

Challenge: Manual logging and lack of site visibility caused delays and hindered real-time issue resolution. Drivers faced unclear instructions and frequent disruption.

Solution: Poweryard's Digital Yard Task Execution and Remote Monitoring to automate task logging and provide 24/7 operational visibility.

Results:

* Elimination of manual logging saved drivers 2 hours per shift

* Managers resolving issues proactively

* Improved yard efficiency and driver satisfaction -

Large Distribution Yard: Eliminated gate guesswork

Challenge: Open yards with no structured check-in left drivers unsure where to go, causing inventory inaccuracies and delays.

Solution: Pre-Check Portal with real-time arrival/departure visibility.

Results:

* Full visibility to off-hour gate activity

* 2 hours saved daily on WMS updates

* $36K in annual labor savings

-

Consumer Goods Warehouse: Smarter dock assignments

Challenge: Without inbound visibility, docks were underutilized and plagued by late arrivals.

Solution: With PowerYard, real-time arrival data enabled proactive dock scheduling.

Results:

* Fewer dock delays and rework

* Better productivity for dock workers

* $36K in annual scheduling gains

-

Food Processor: Document Accuracy and Dock Flow

Challenge: Manual check-ins and document errors caused bottlenecks, disputes, and costly follow-ups.

Solution: Driver Pre-Check and Document Imaging from PowerYard enabled accurate data and BOL uploads before arrival.

Results:

* Check-in time reduced by over 30%

* $16K in labor savings + $8K in document error prevention annually

* $52K in annual dock scheduling improvements

Ready to Transform Your Yard?

Discover why operations leaders rely on PowerYMS to streamline yard ops, accelerate gate processing and reduce detention fees.

.png?width=845&height=560&name=Untitled%20design%20(21).png)

.png?width=845&height=560&name=Untitled%20design%20(21).png)